Design coordination and technology coordination for project success

The University of Kansas Health System hired McCownGordon and Linbeck Joint Venture to build their Proton Therapy Facility. TUKHS set a goal to see the first patient in 2022. With that date in mind, the project team worked backwards to accomplish this goal. The team knew the gantry takes 14 months from procurement to arrival and 12 months to calibrate. With this schedule, the team utilized BIM modeling and other technology to ensure quality control and meet the required deadline.

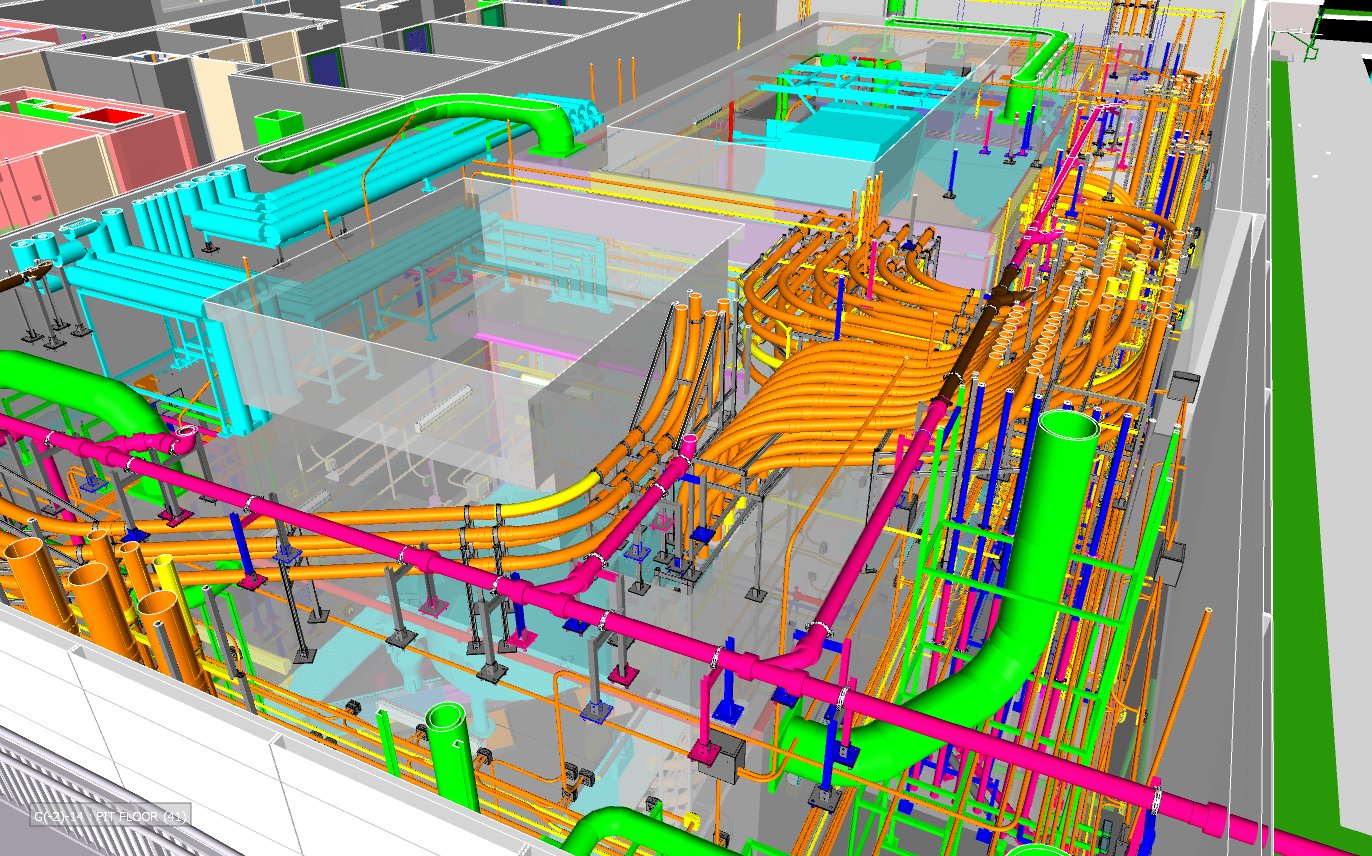

To ensure the equipment vendors’ pathways, as well as radiation safety around the treatment room were completed to the highest standards, heavy coordination among multiple trades was the utmost importance. The construction team only had one chance to be successful and the only way to achieve success was to utilize BIM modeling of all parts and pieces prior to any install taking place onsite.

Although the concrete sections of the vault ranged from 6’ to 12’ thick, areas were heavily congested with conduit raceways, mechanical piping, rebar and embeds. To ensure the surrounding areas were shielded from the radiation within the vault, each item that penetrated the vault surfaces had to have at least two 90 degree turns or bends.

The project team utilized prefabrication assemblies in lieu of the traditional stick build process for in-field operations and installations. Assemblies of racked conduits or technical gas lines would arrive as needed then were quickly hoisted and installed in sequence using uni-strut racking supports.

Clash detections of different systems and extensive team reviews were completed weekly for roughly four months to yield a complete and coordinated building. Utilizing the BIM model onsite as well as virtual 3D photo reviews with the design team and owner via virtual meetings kept multiple eyes on every detail to ensure success within each concrete pour. The use of advanced technology made the project a success.